| PROGRAMMING SCHOOL | Raspberry Pi-F5 / T5 |

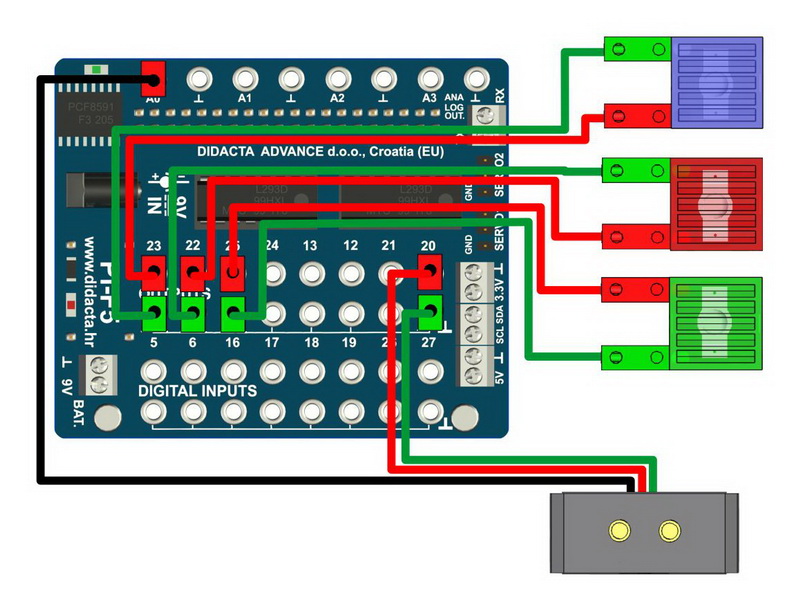

| 1. | KAMERA - LED CONTROL (OPEN CV) | 13. | IR SENSOR (ANALOGUE) | ||||||

| 2. | ENCODER MOTOR - HALF STEP - BETTER PRECISION | 14. | IR SENSOR (DIGITAL) | ||||||

| 3. | ENCODER MOTOR - STEP - LESS PRECISE | 15. | DC MOTOR - SPEED CONTROL (ANALOGUE) | ||||||

| 4. | RX - TX COMMUNICATION | 16. | DC MOTOR - TWO WAYS ROTATION (DIGITAL) | ||||||

| 5. | I2C COMMUNICATION | 17. | DC MOTOR - ONE WAY ROTATION (DIGITAL) | ||||||

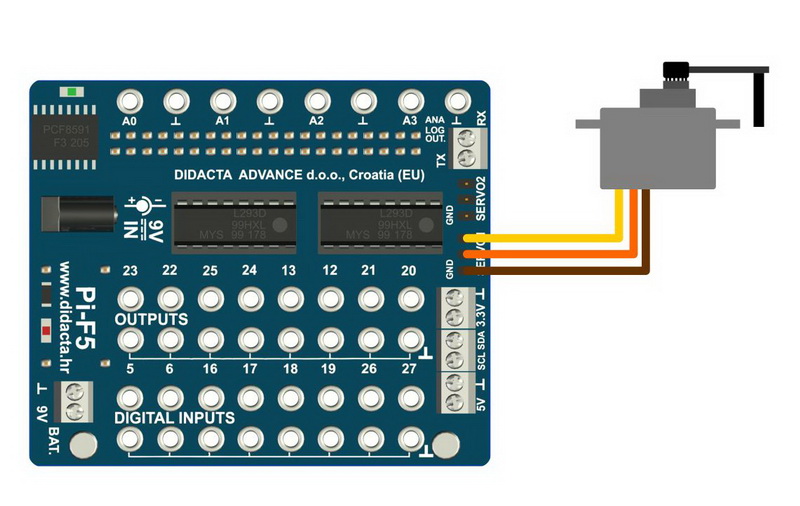

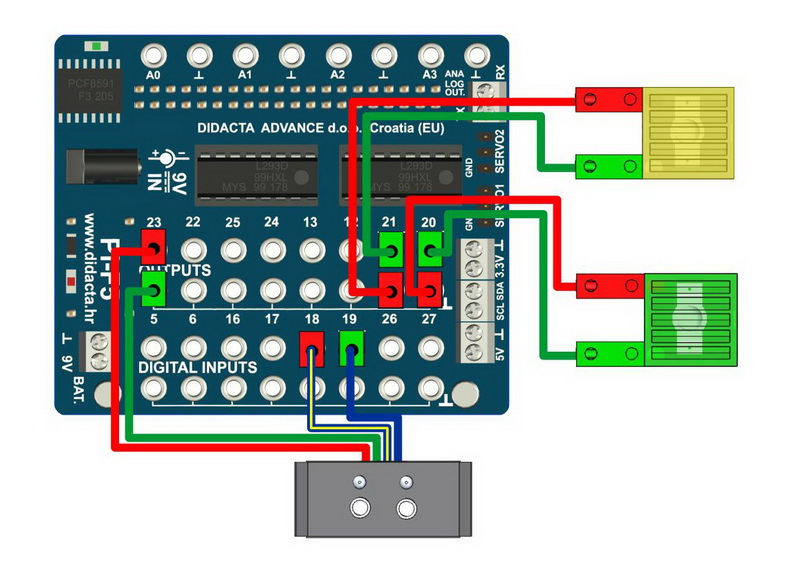

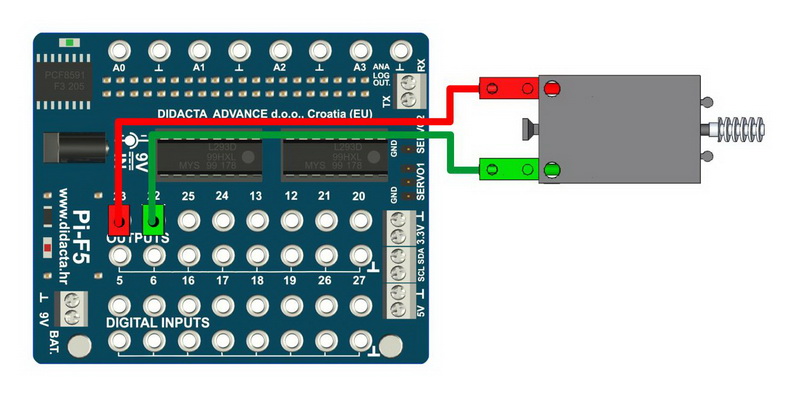

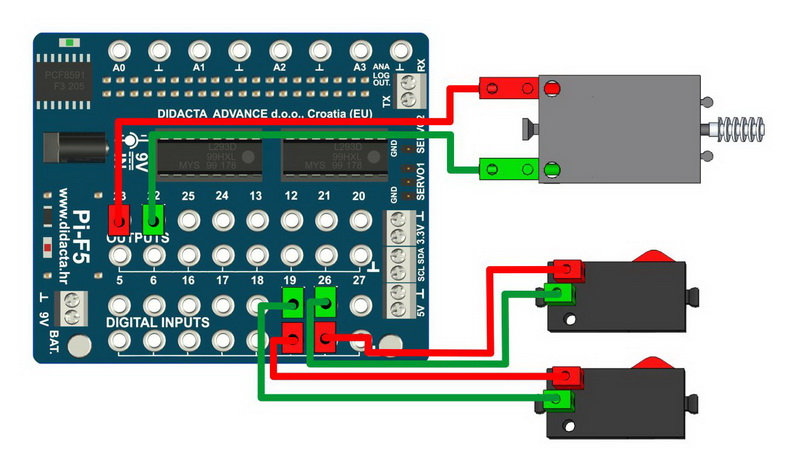

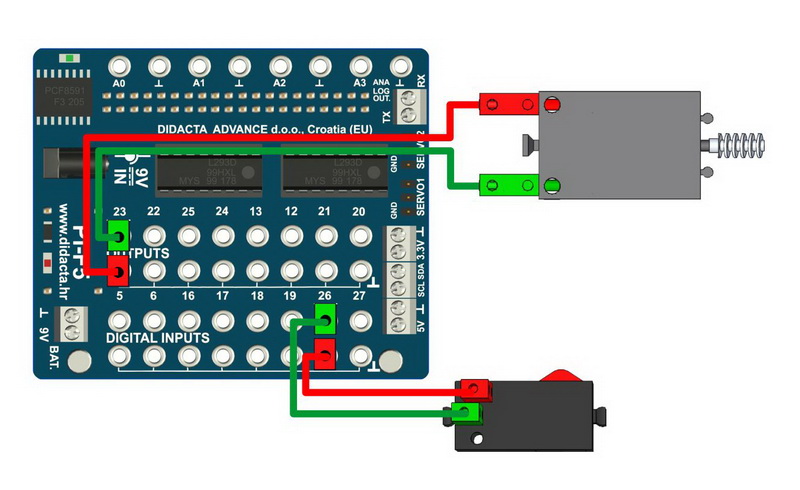

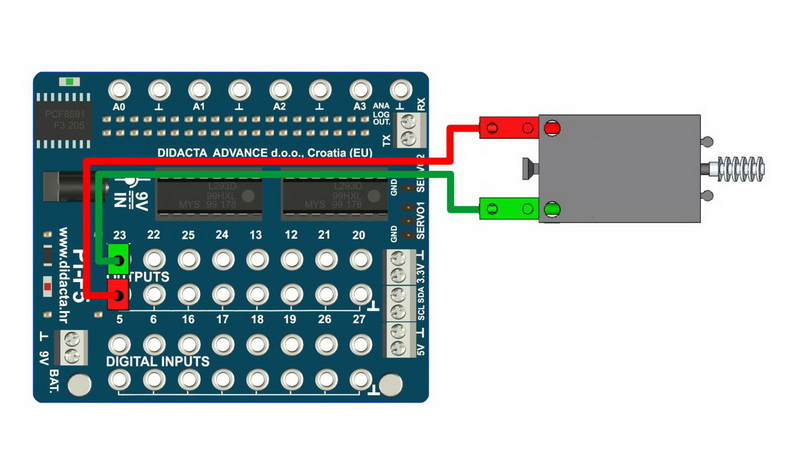

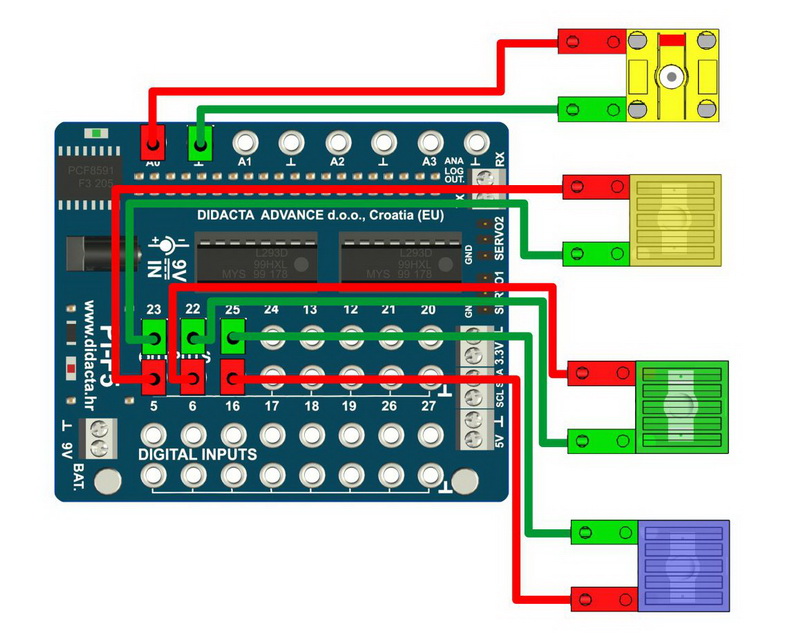

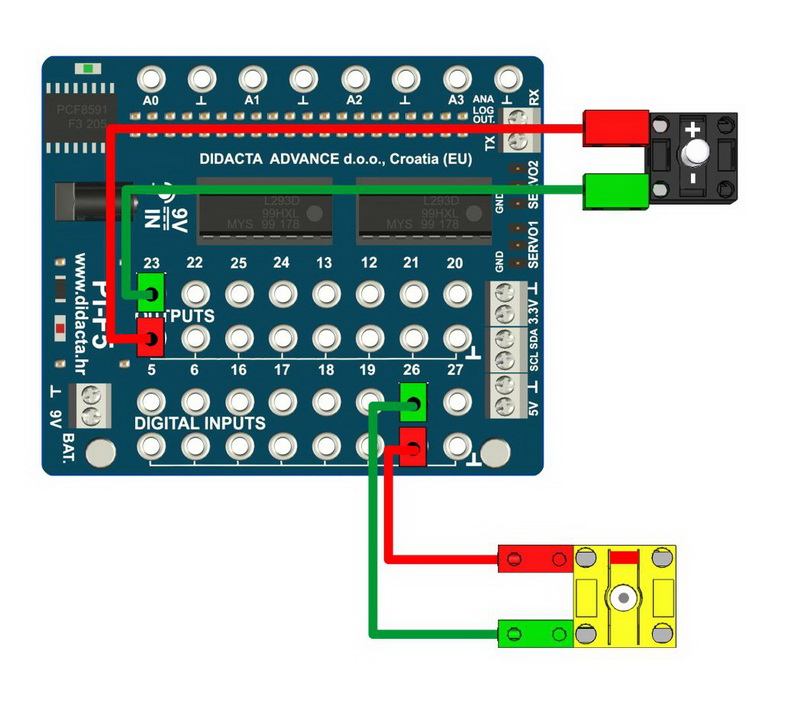

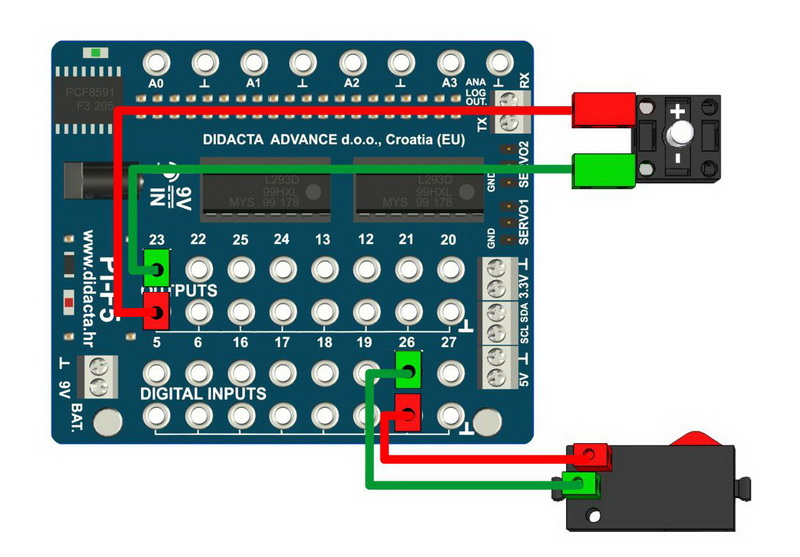

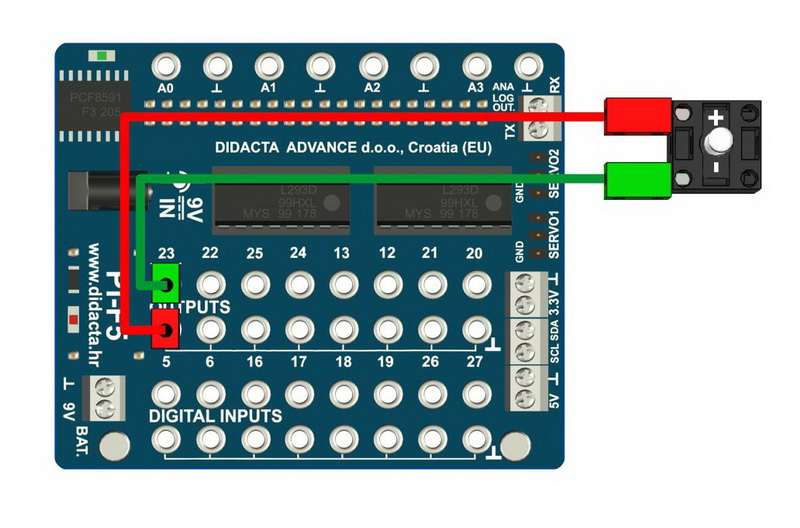

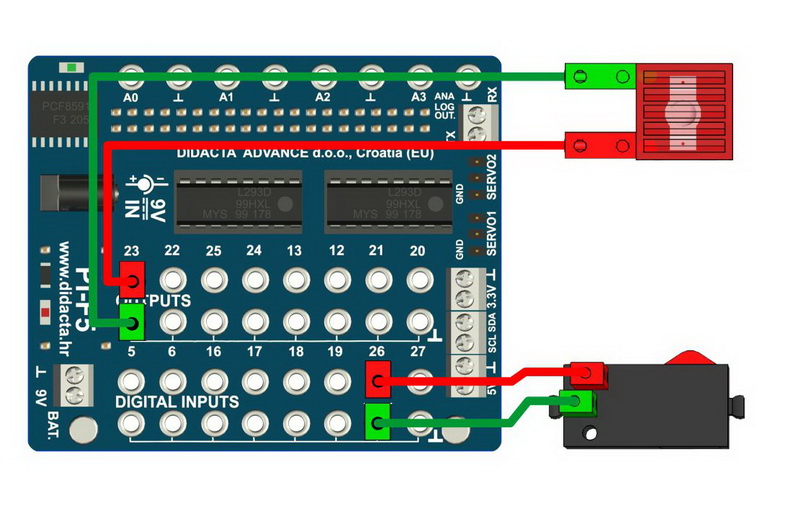

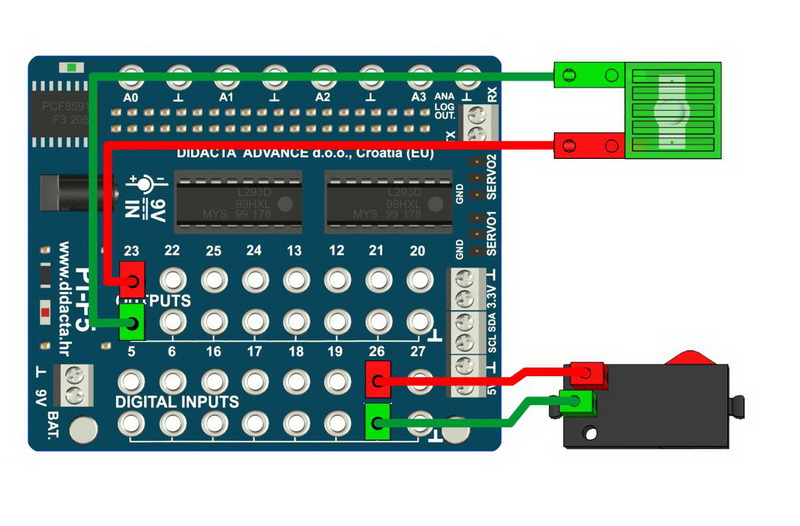

| 6. | SERVO MOTOR | 18. | DC MOTOR (DIGITAL) | ||||||

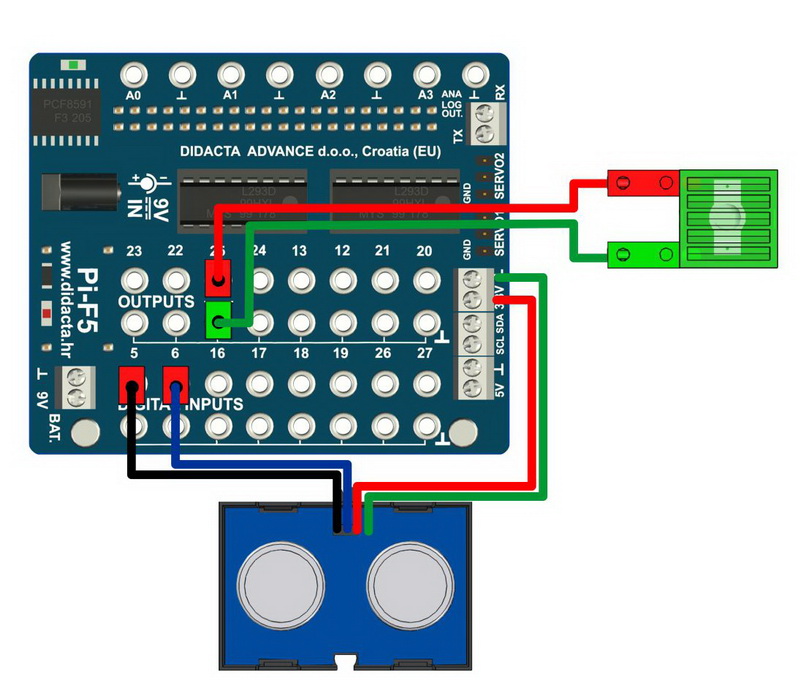

| 7. | ULTRASOUND SENSOR (ANALOGUE) | 19. | PHOTO SENSOR - LED LIGHT (ANALOGUE) | ||||||

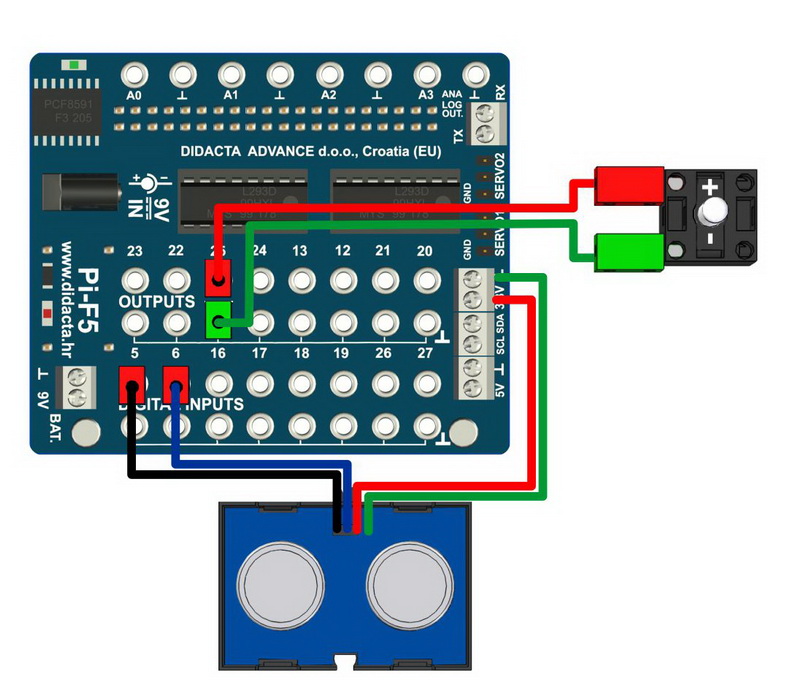

| 8. | ULTRASOUND SENSOR (DIGITAL) | 20. | PHOTO SENSOR - LED LIGHT (DIGITAL) | ||||||

| 9. | COLOR SENSOR - BLACK LINE | 21. | LED LIGHT - MICRO SWITHCH (ANALOGUE) | ||||||

| 10. | COLOR SENSOR - COLORS | 22. | LED LIGHT (ANALOGUE) | ||||||

| 11. | MAGNETIC SENSOR (DIGITAL) | 23. | LED LIGHT - MICRO SWITCH (DIGITAL) | ||||||

| 12. | HEAT SENSOR (ANALOGUE) | 24. | LED LIGHT (DIGITALY) | ||||||

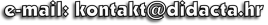

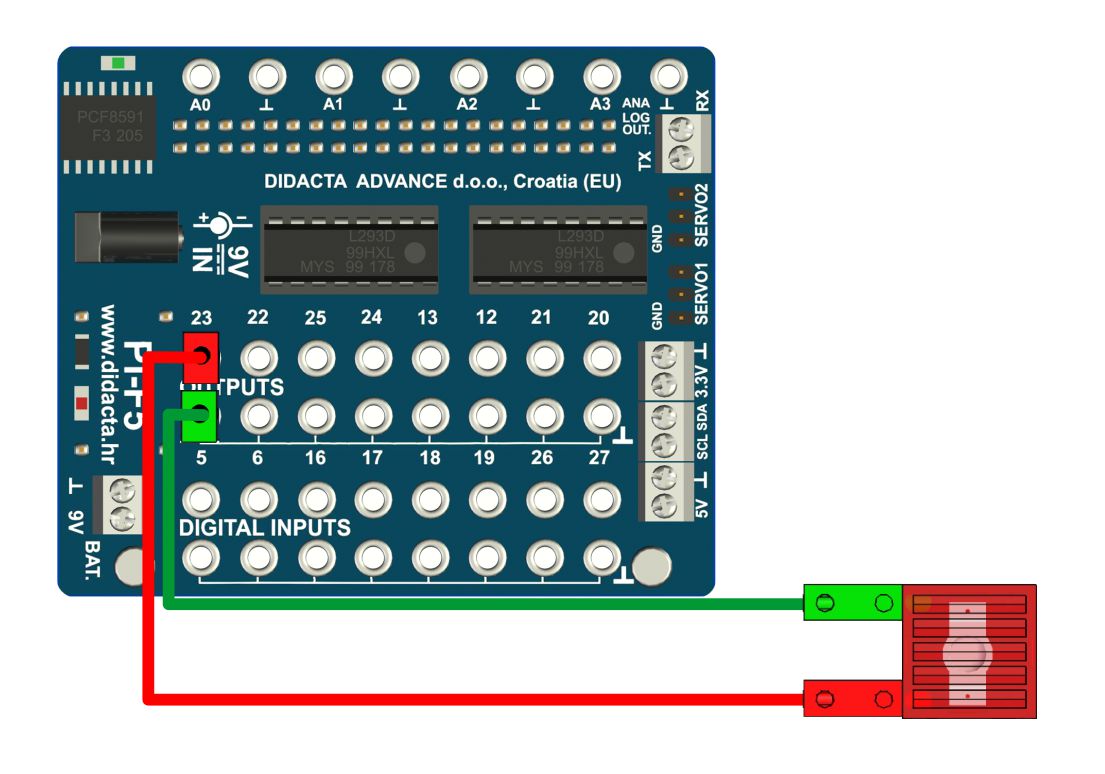

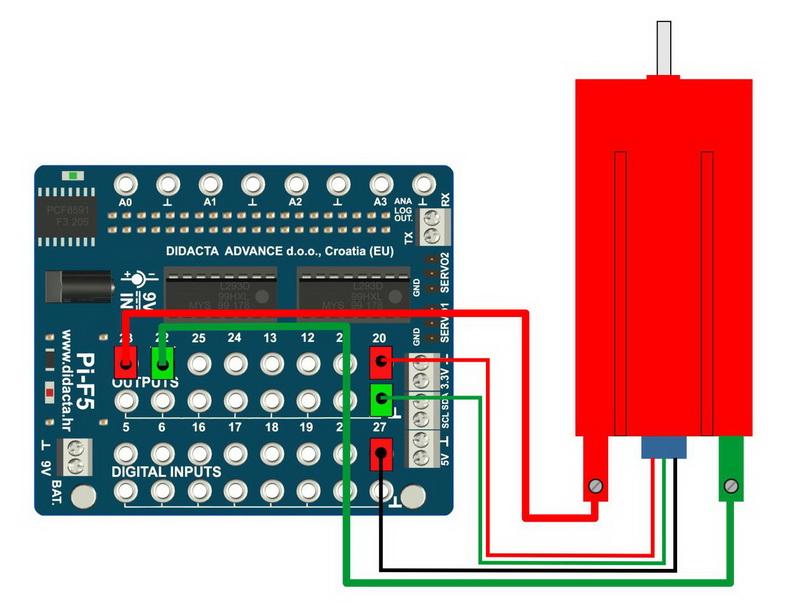

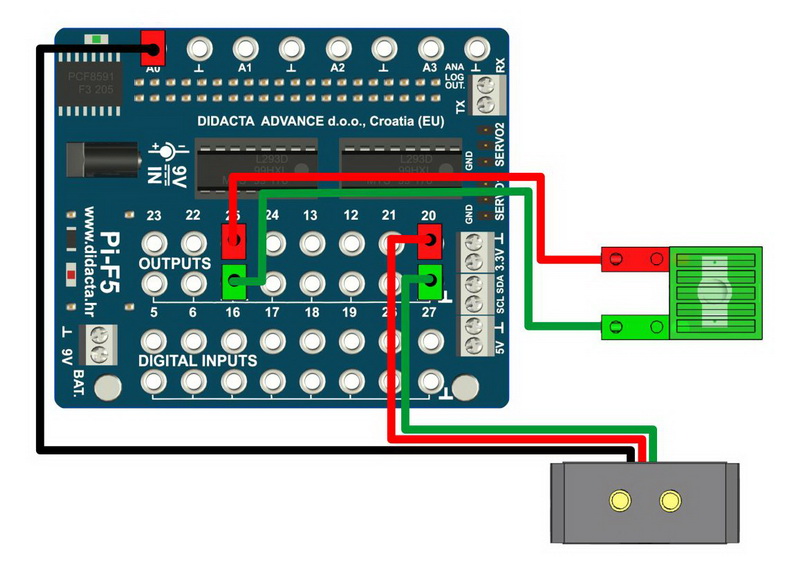

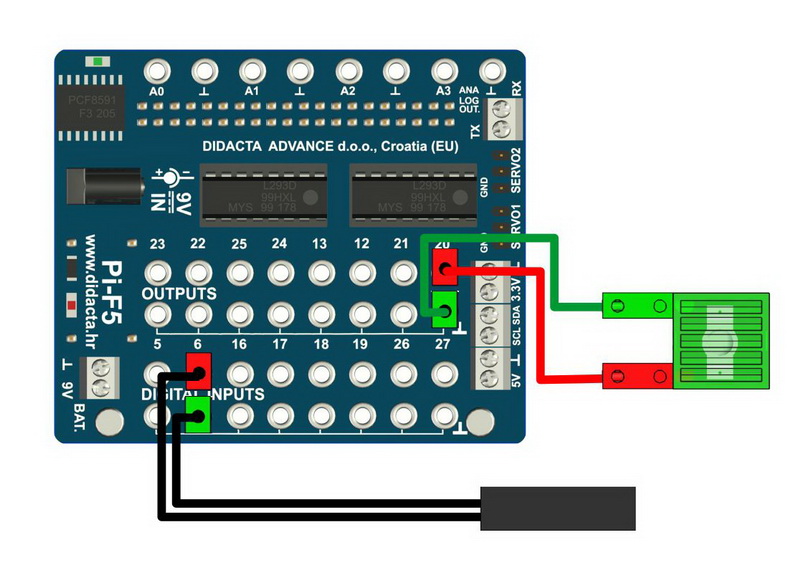

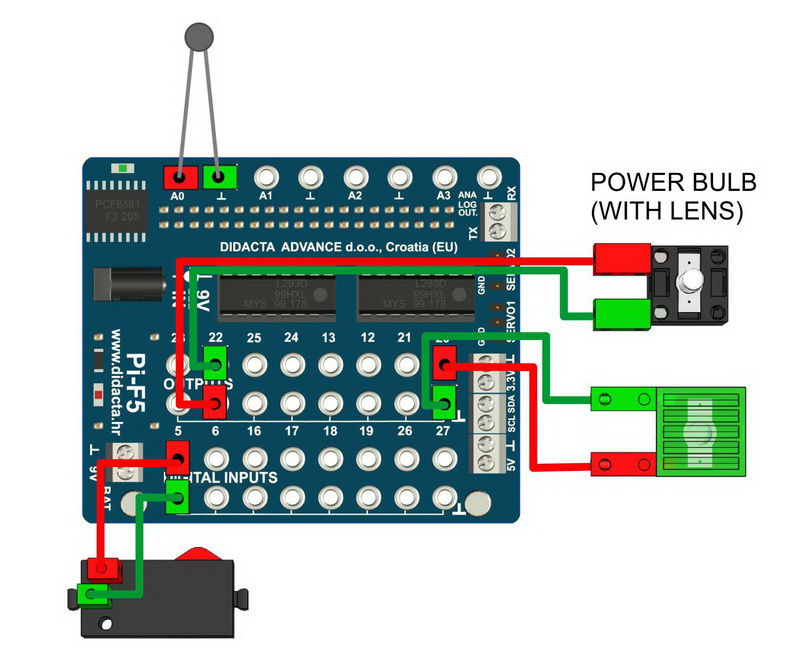

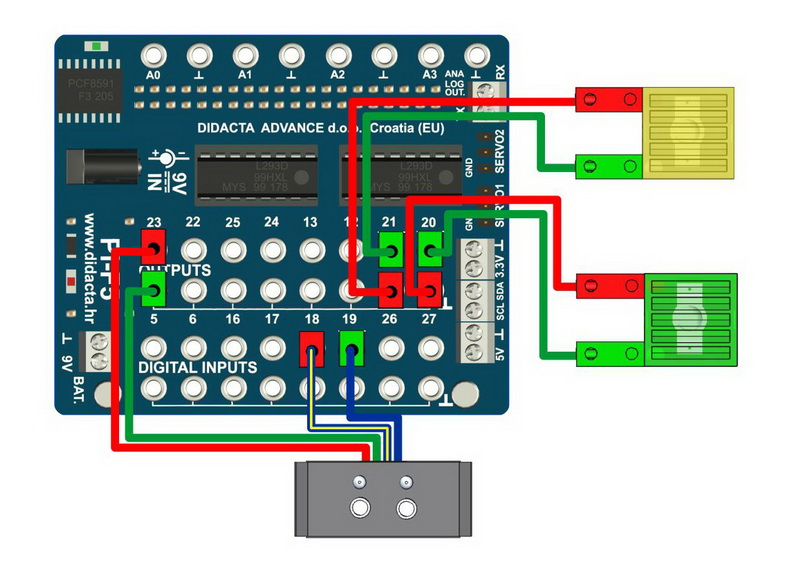

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||